PF Filter

All-round system for the highest filter output

All-round system for the highest filter output

The PF Filter is suitable for cleaning and bath maintenance for pre-treatment systems in the surface treatment /automobile industry / supplier industry as well as for the filtration of cooling lubricants.

Quality improvements and service life extensions of the process medium can be realised with it.

Through these factors, there are also substantial cost savings in terms of chemicals used, less waste disposal and cleaning costs.

Depending on the quantity throughput, different filter fleece widths are available.

The filtration grade is essentially determined by selecting the filter fleece; fineness grades up to 10 μm are possible. The formation of a filter cake at the woven filter medium enhances the filtration action.

The vacuum created by the PF Filter under the filter fleece ensures a low consumption and maximum exploitation of the filter fleece.

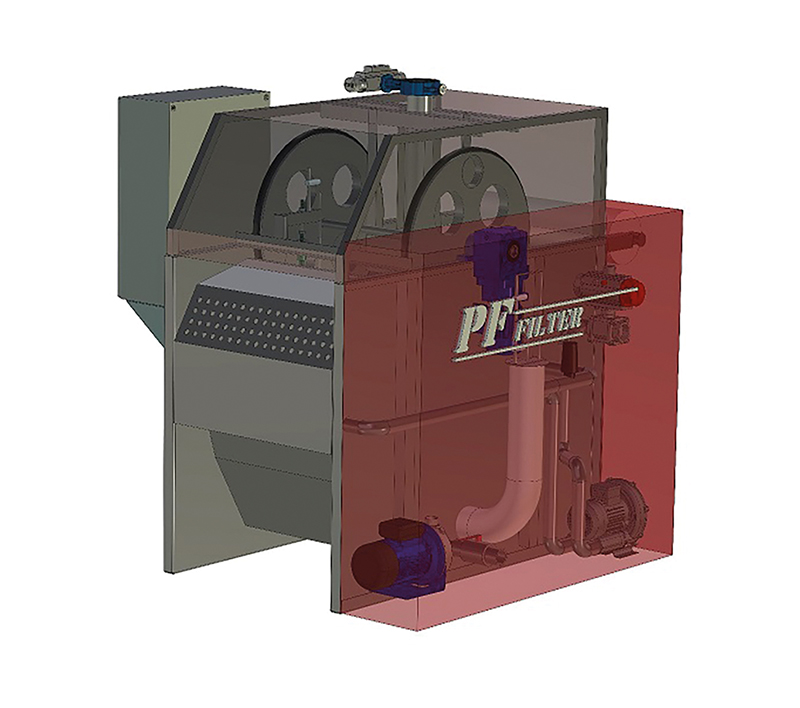

Our PF filter is a fully automatic filtration system made with a round filter bed and additional vacuum support.

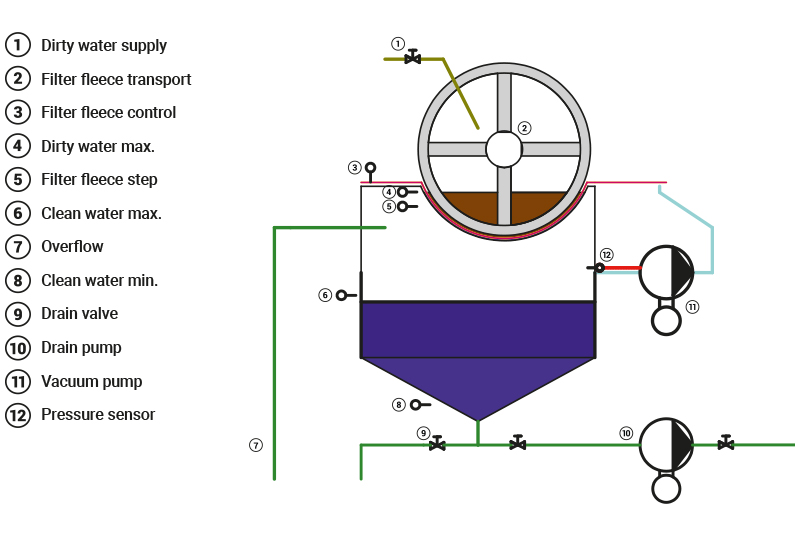

The medium to be filtered is led via an inflow distributor into the hemispherical filter chamber.

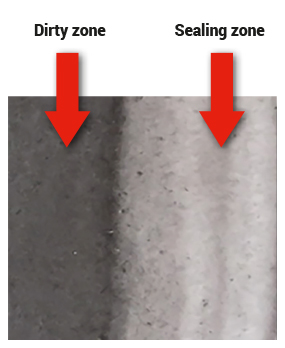

The filter fleece is sealed by means of two synchronous wheels touching the hemispherical supporting structure.

The elastic seal ensures optimum sealing of the dirt chamber from the clean chamber.

Owing to the continuous fouling of the woven filter medium, the medium level in the dirt chamber increases up to a certain height; once a certain level is reached, the vacuum pump also gets switched on. Only when the maximum medium level is reached is the filter fleece moved forward.

Maximum exploitation of the filter fleece with minimum energy consumption

Frequency-controlled regulation of the vacuum pump: this results in a further saving of energy with the best possible exploitation of the filter fleece

The filtered medium gets discharged into the output tank fitted below the filter fleece; a level controller monitors the level in the output tank and activates a recirculating pump which pumps the medium back into the process.

Sludge dewatering, wastewater treatment

The screen structure is very clear and can be operated intuitively.

The process values are displayed clearly in the form of a bar chart.

Operational states are shown in colour: green = in operation, red flashing = faults

The lateral sealing of the dirty water and the woven filter from the clean water area is achieved by means of simultaneously rotating wheels with an elastic sealing surface arranged laterally.

Adjustable vacuum: the vacuum control and hence the rotational speed of the side channel compressor is achieved by means of a frequency converter. As a result, only the quantity of energy that is required is consumed, no bypass for excess vacuum

Simple intuitive operation via the operating panel

Display of all the process-relevant parameters on the operating panel

Large bandwidth of different filter fleece

Selection of high-quality components of renowned manufacturers

Vacuum pump → Gardner-Denver

Drive motor → SEW

Compact construction, as a result, small footprint (approx. 1.5 m²)